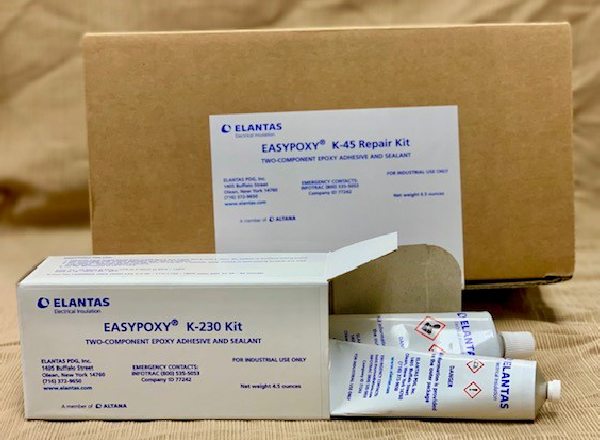

Our product range includes CONAP®, Conathane®, EASYPOXY®, Bectron®, and Epoxylite® and offers innovative solutions for specialty filtration, high temperature, performance and industrial adhesives as well as specialty adhesive primers.

Technical Data Sheet or a Material Safety Data Sheet

Download