Complexity of the Drying and Curing of Printed Electronics

Speed plays a decisive role in the field of printed electronics. Accordingly, the drying and curing characteristics determine the choice of the materials used. The focus is increasingly on alternatives to the conventional oven drying method.

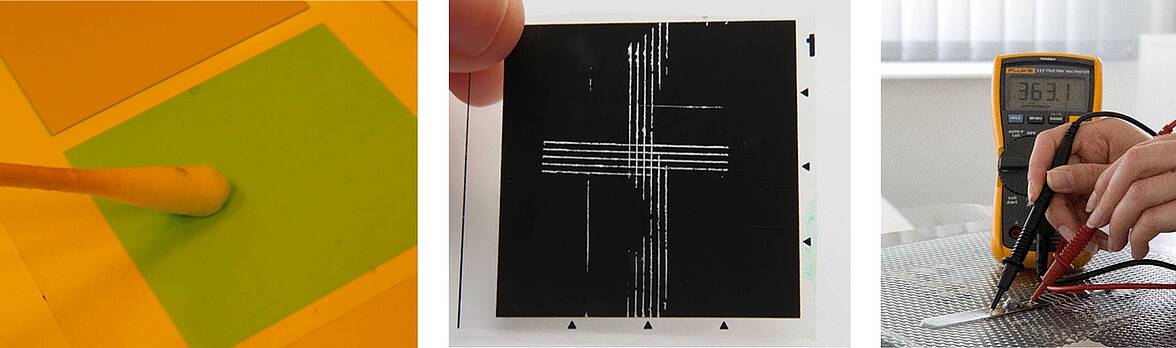

The drying and curing of functional pastes influences the resulting application properties. The definition of adequate drying and curing can therefore differ in accordance with the requirements. A variety of testing methods exist for this.

In order to determine the right definition and testing method it is important to understand that there are differences resulting from the chemistry of the products. These differences significantly influence the drying and curing processes. In the field of printed electronics, a distinction is made primarily between physically drying, thermally curing and UV-curing products.

In particular, it is necessary to clearly distinguish between “drying“ and “curing“.

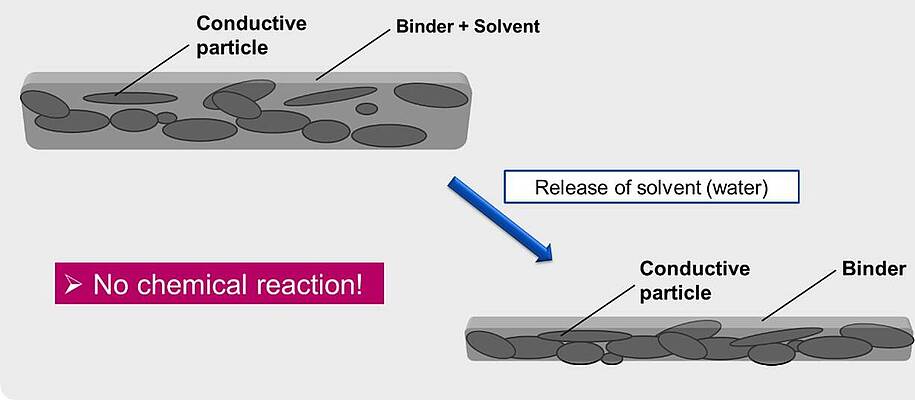

Physical drying:

Physical drying results in the formation of a dried film due solely to the evaporation of the solvent used. No chemical reaction occurs. Drying takes place under the influence of heat, for example in an oven or with near-infrared/infrared modules.

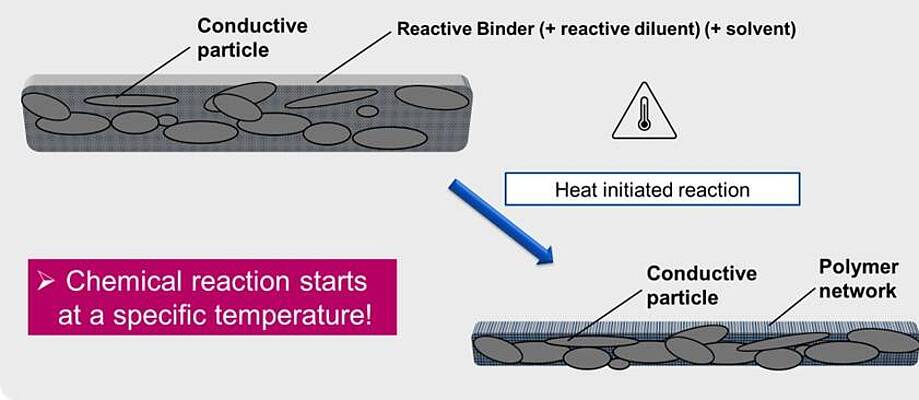

Thermal curing:

In contrast to physical drying, thermal curing requires a minimum temperature in order to initiate the chemical reaction of the reactive binder and to induce polymerisation.

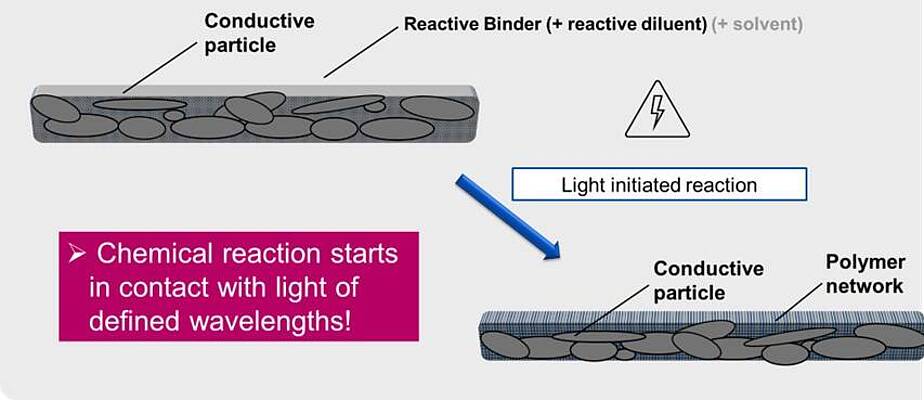

UV-curing:

With UV-curing products a chemical reaction also occurs, which in contrast to thermal curing is initiated by UV-light. Here, it is decisive that the light source used furnishes the necessary wavelength for activating the photo-initiators in the product. Mercury vapour lamps or LEDs are often used. Besides the choice of the right light source, a minimum UV-dose is required to ensure sufficient curing.

Besides the drying and curing types described there are a number of other possible mechanisms, which can be product-specific. To some extent, combinations of different mechanisms are also possible. Applications are often determined and limited by the substrate employed. Furthermore, every product type has advantages and disadvantages in respect of the chemical and mechanical properties. In order to find the right product for your application, an exchange between the paste supplier and user is recommended

We would be pleased to answer your questions directly and offer technical support for the realisation of your projects with suitable products. Simply send us an email to: AdvancedPrinting@altana.com

Further information about the products described is available under the links below. You’ll find relevant recommendations for further insulating and conductive screen-printing pastes there and in our technical datasheets. Electronic Products from ELANTAS Europe