Printed electronics enables a broad scope of potential technical and creative applications for different fields. A good example from practice are printed heaters. The heating elements can be printed onto standard film or as a self-bonding adhesive label. Compared with the frequently mentioned RFID or NFC antennas, printed electronics offers many more possibilities. Whether for the steering wheel, the seat or for sensors in the autonomous driving area – printed heaters are already in use in many automotive applications and offers numerous advantages here.

Heating device during heat up phase (Temperature different is from red around 40°C and yellow 38°C to blue 36°C).

Watch our video.

Particularly with a car, reliable functioning of the sensors is necessary, especially in the presence of snow and ice. Heating elements are attached directly to or integrated into the sensor. The heating elements can be printed onto flexible substrates, for example onto polycarbonate, PET or PI films. The final temperature determines which film is used. As a rule, for the applications described the printed heaters are not visible and the heat is, for example, emitted indirectly. Classical silver, copper or carbon pastes are well suited for these applications. However, there are also transparent heating elements which can be printed onto glass, for example in order to heat mirrors, windscreens and rear windows. In all cases, contact to a current source is required. Furthermore, the current load and capacity of the voltage source must be matched to the design, the size and the required temperature. This requires the continuous control and stability of the screen-printing machine printer in order to ensure the correct coating thickness of the printed conductive ink. A change in the coating thickness would result in overheating or a malfunction. Other than with graphical printing, for printed electronics it is necessary to ensure a stable, uniform coating thickness and conductivity, whereas the coloring is less important.

Many companies already specialize in the conception and design of such heating elements. The printability of such functional screen-printing pastes has been developed optimally and user-friendly. This enables long screen times together with fast drying.

Besides silver- and carbon-based pastes with fixed resistance, pastes with adjustable resistance play an important role in the area of printed heating. These pastes allow the precise adjustment of the required resistance for the heating structure.

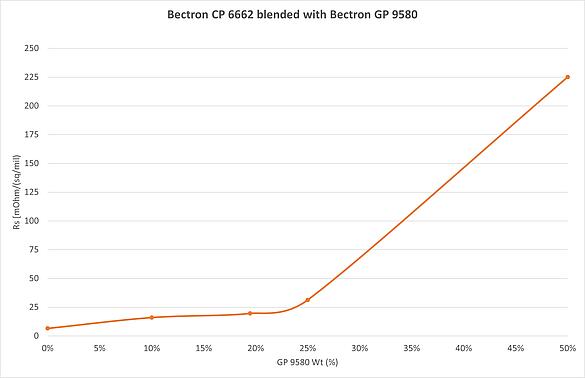

For such requirements ELANTAS Europe offers e.g. the Bectron® CP 6662 silver ink, the resistance of which can be very well adjusted with Bectron® GP 9580 carbon paste. In its original state, Bectron CP 6662® has a sheet resistance of 9 mOhm/sq/mil, and with the addition of e.g. 25% Bectron GP 9580® the resistance can be adjusted to 31 mOhm/sq/mil or e.g. with 50% Bectron® GP 9580 to 225 mOhm/sq/mil. After adding Bectron® GP 9580 to Bectron® CP 6662 it is necessary to mix the components thoroughly with a blade agitator. Otherwise, non-homogeneous printed results may occur during printing.

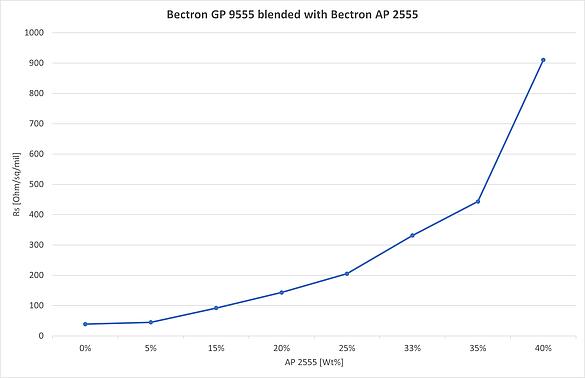

For resistance values in the Ohm range we offer the Bectron® GP 9555 carbon paste, with a resistance of 40 Ohm/sq/mil. This can also be precisely adjusted with the Bectron® AP 2555 adjusting paste. With the addition of e.g.15% Bectron® AP 2555, the resistance can be adjusted to 92 Ohm/sq/mil or e.g. with the addition of 40% Bectron® AP 2555 to 910 Ohm/sq/mil. After adding Bectron® AP 2555 to Bectron® GP 9555 it is also necessary to mix the components thoroughly with a blade agitator. Otherwise, non-homogeneous printed results may occur during printing.

ELANTAS Europe is a leading manufacturer of liquid insulating materials for electrical machine engineering and the electronics industry The printed electronics product segment offers an extensive assortment of functional screen-printing inks for applications such as membrane keyboards, functional interfaces, inmold electronics, hybrid electronics, sensors, RFID antennas, and electroluminescent inks.

You’ll find additional information on the products described under the link below. There and in our technical datasheets you can also find relevant recommendations for other insulating and conductive screen-printing pastes: https://www.elantas.de/europe/products/printed-electronics/products.html

We will be pleased to answer your questions directly and offer suitable products in support of the technical implementation of your products. Simply send us an e-mail: AdvancedPrinting@altana.com