Introduction

Today’s consumers are looking for smarter technology to make their daily routine simpler and more efficient. Printed electronics has already been an important part of this development for several decades. Versatile design scope, minimum use of material, cost-efficient substrates and additive printing techniques are key factors for sustainable products here.

Applications are frequently executed on flexible substrates in screen-printing. Depending on the pastes employed, in each printing step between 0.5µm and 30µm are applied. The screen-printing process has established itself as a result of its coating thickness variability. The choice of a suitable screen cloth alone allows the printing of both low-viscosity and highly pasty materials with a high pigment fraction. Screen-printing therefore has a decisive advantage compared with inkjet, flexographic printing and gravure printing. Very thin and lightweight components, such as sensors in batteries, can be placed with minimum space requirements. This represents an enormous advantage for electromobility. Every kilogram weight saved increases the range and is thus a competitive advantage. Printed electronics has also already found its place in the aerospace industry. The weight reduction enables savings of kerosene and is not only a commercial success, but also contributes to sustainability.

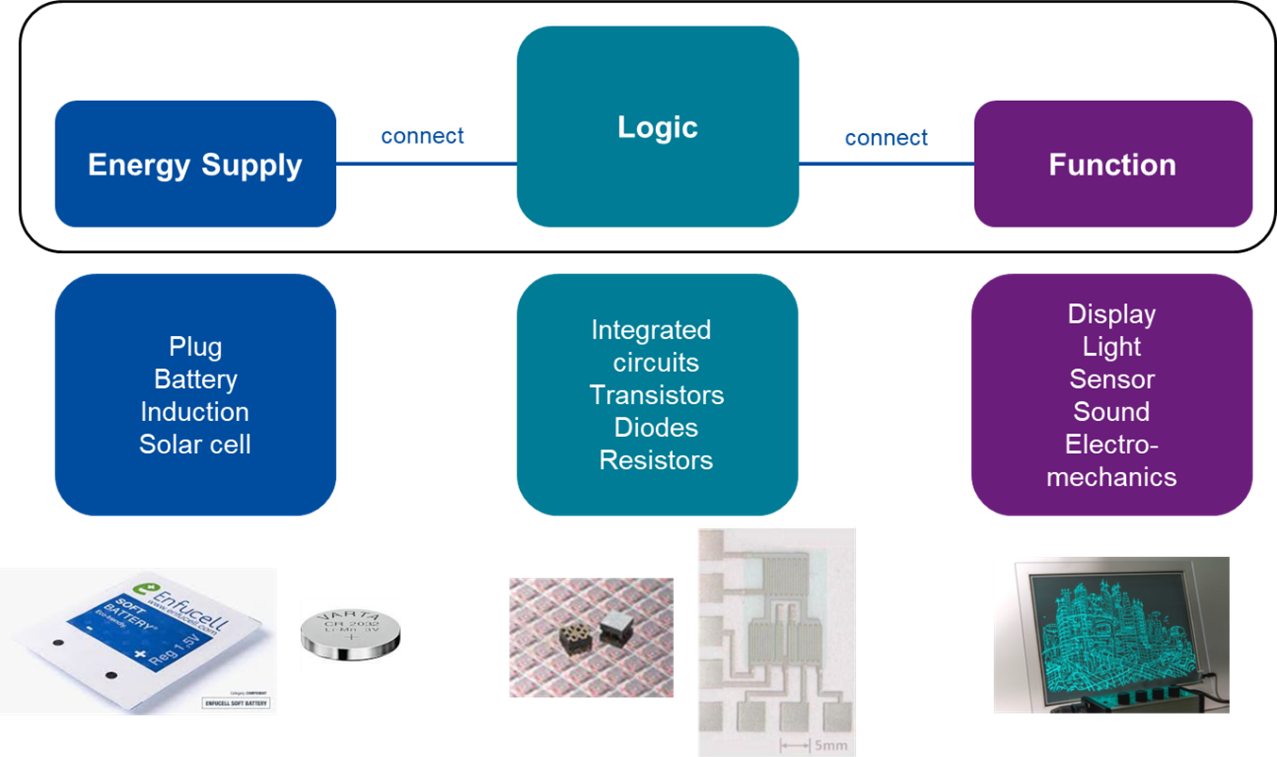

“Printed Electronics“ functions on the basis of three main pillars.

- The first element is the energy source. This can be a classical electrical connection, a battery, an inductor or even a solar cell, whereby even batteries and solar cells can be printed today.

- The logic, based on silicon chips, as printed solutions are not yet available.

- Possible functions are e.g. displays, lighting, sensors, sound, and electromechanical functions.

Functional principle of printed electronics

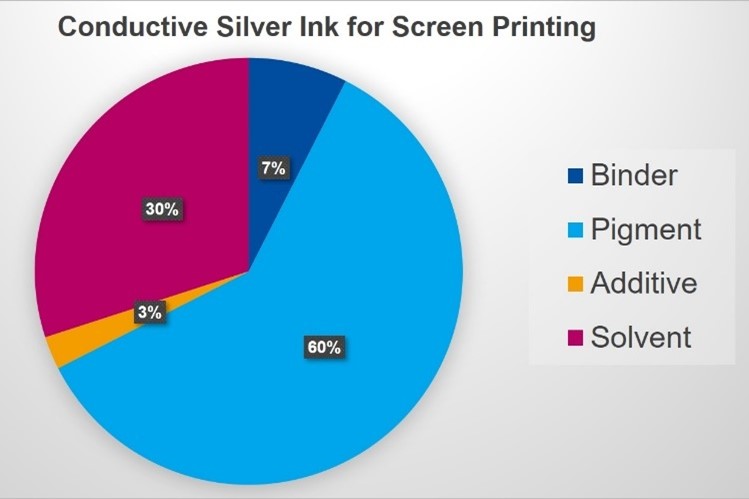

In this article we would like to show that “printed electronics“ comprises not only RFID or NFC labels. The following examples make use of conductive pastes with silver and graphite pigments and insulating printing lacquer. Silver has the decisive advantage that – contrary to copper – its oxide layer is also conductive. This property enables the formulation of highly conductive pastes and flexible binders. Compared with graphical ink, a very high functional pigment fraction is required.

Conductive Silver Ink for Screen Printing

Applications

In combination with conventional electronic components, such as chips and LEDs, it is possible to realize a great many applications.

Labels

In the past, a lot has happened in the area of printed labels. Label printers are increasingly discovering the possibility to make a classical label smarter. The following applications already exist:

- Initial opening protection by printed conducting tracks, which are destroyed on opening and then signal to the chip “Attention! The product has been opened or manipulated“.

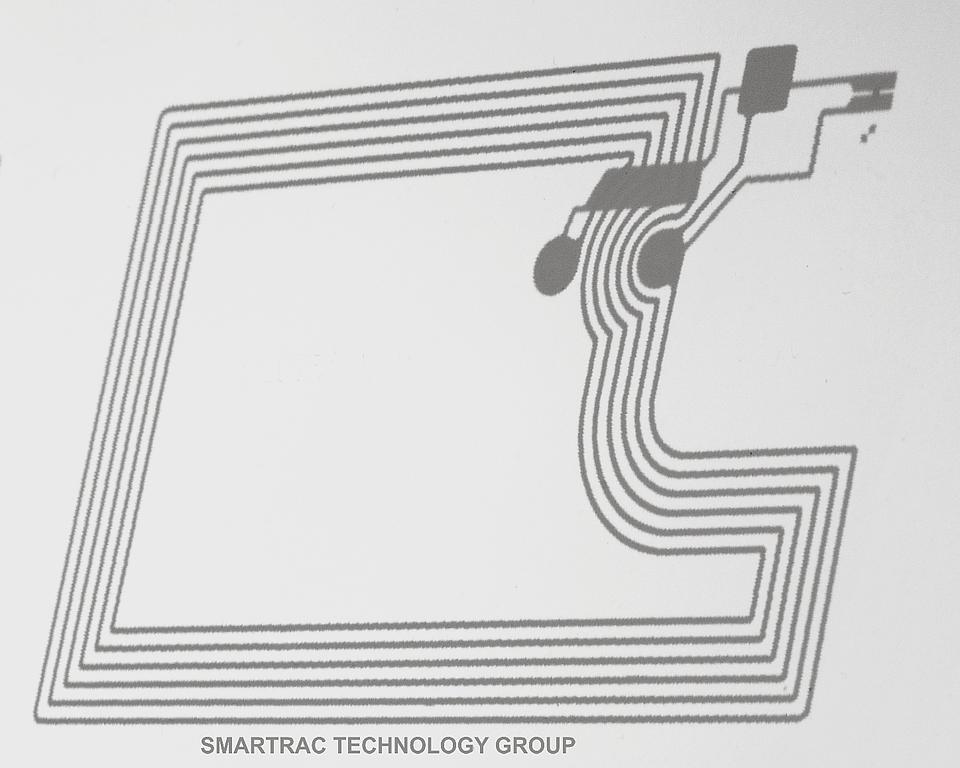

- RFID or NFC antennas in combination with a chip that enables contact-free payment and can also offer further information about the respective product. This reduces the use of costly multi-layer labels.

- RFID antennas for a smart warehousing and logistics system and simplified inventory.

- Temperature loggers for application with sensitive goods.

For the case of NFC, antennas are printed with silver paste and insulating paste, in contact with a corresponding chip. These conducting tracks can be made either by sheet-fed printing or also cost-effectively by roll-to-roll printing. For this purpose, ELANTAS Europe offers a unique UV-hardenable, conductive silver screen-printing ink. The corresponding insulator is also UV-hardenable.

Smartrac NFC antenna

Lighting

Luminous elements are known from many areas, e.g. the keypad lighting of remote control modules can be realized with printed electroluminescent surfaces or with LEDs on printed conductive silver tracks. Here as well, ELANTAS Europe offers UV-cross-linking ink systems.

EL column

Solar cells

In the flexible solar cell area, electrical connections can be printed by means of silver pastes. This enables the production of flat, flexible and individual solar cells. The market is interesting and, particularly in combination with printed, rechargeable batteries, offers considerable potential. Here, ELANTAS Europe offers special highly conductive silver dyes for the printing of narrow conducting tracks which enable maximum solar cell output.

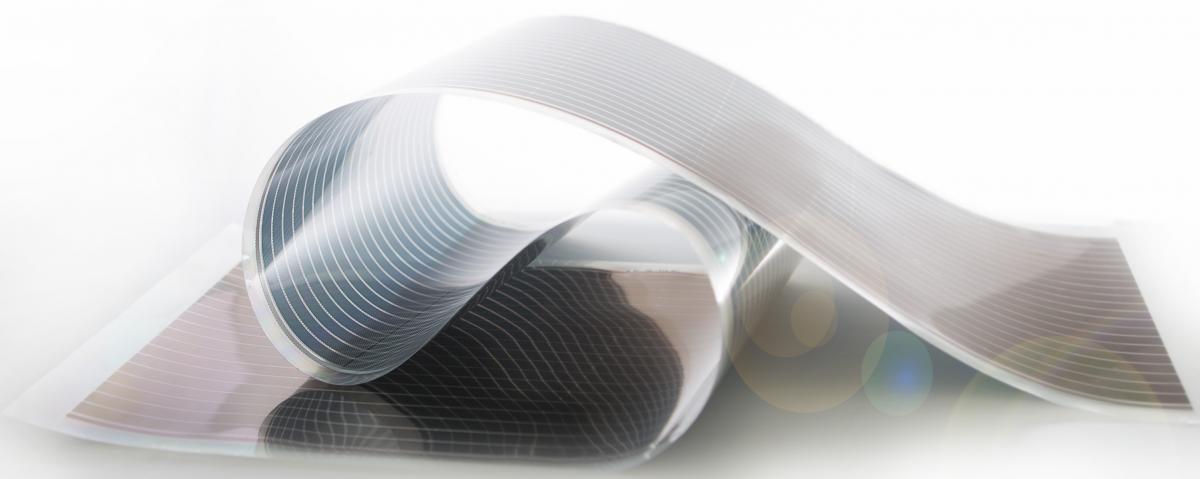

Printed solar cell from the Armor Company Group

Heating elements

Printed heating elements are found in many measuring and processing devices and also in other applications. In vehicles, these can even be integrated into textiles, for example as seat or steering wheel heating. Other automotive applications, such as window, sensor and battery heating, can also be printed. Particularly in regard to the autonomous driving of the future, it is important that sensors remain free of ice and snow. This requires that the sensors be heated directly on the sensor itself, and this is only possible with flat and flexible conducting tracks.

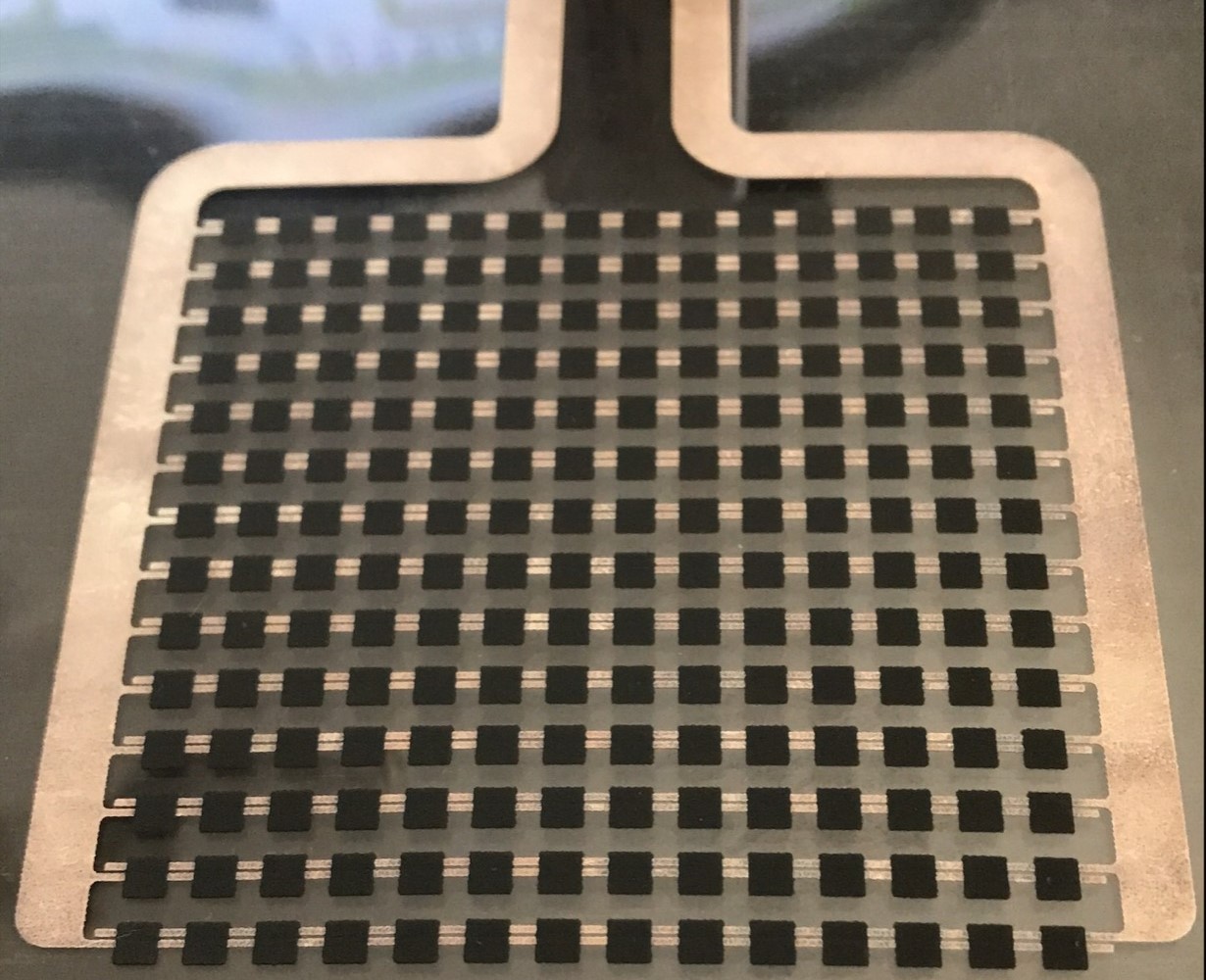

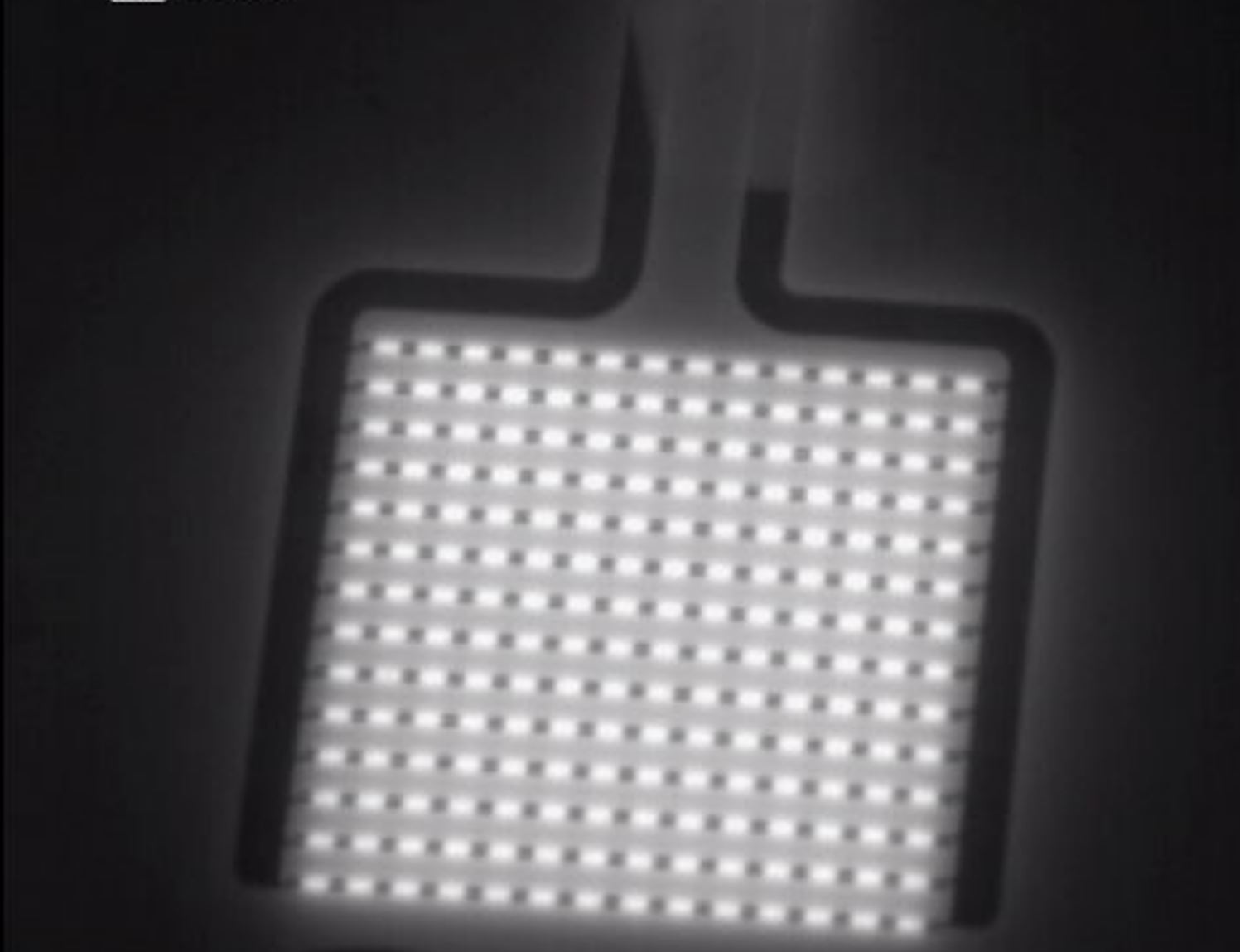

Printed heating 1

Printed heating as a thermal image

Acoustics

In the field of acoustics, it is now possible to print entire loudspeaker systems on a web-fed printing machine. Furthermore, it is also possible to realize the supply cables for very flat loudspeakers, such as the speaker of the Dutch company FINAL AUDIO, with its unique flat high-end systems. Here, ELANTAS Europe offers the fitting ink system.

Source: Final Audio Speakers

Sensors

Sensors are clearly one of the biggest fields of application for printed electronics. An example of this is humidity sensors, which can find use with flat roofs. Here, a narrow, flexible conducting track can be integrated into the roof. In the event of a leak, a short circuit is detected. The resulting alarm early on can prevent costly consequential damage. Furthermore, safety foils which protect card reading devices against manipulation also find use. When the conducting tracks are damaged by unauthorised access, the device registers this and is deactivated. Another common application is the use of pressure sensors, for example for car seats. The so-called seat belt reminders (SBR sensors) trigger an alarm as soon as a passenger’s seat belt is not attached.

Electrochemical sensors for blood sugar measurements are found in the medical sector. A chemical reaction with the blood sends an altered electrical signal over the printed conducting tracks, which is then processed by an electronic evaluation system. In addition, there are medical applications such as intelligent bandages and wound dressings, which support wound healing by the measurement of moistness or by thermal treatment.

Human Machine Interfaces (HMI)

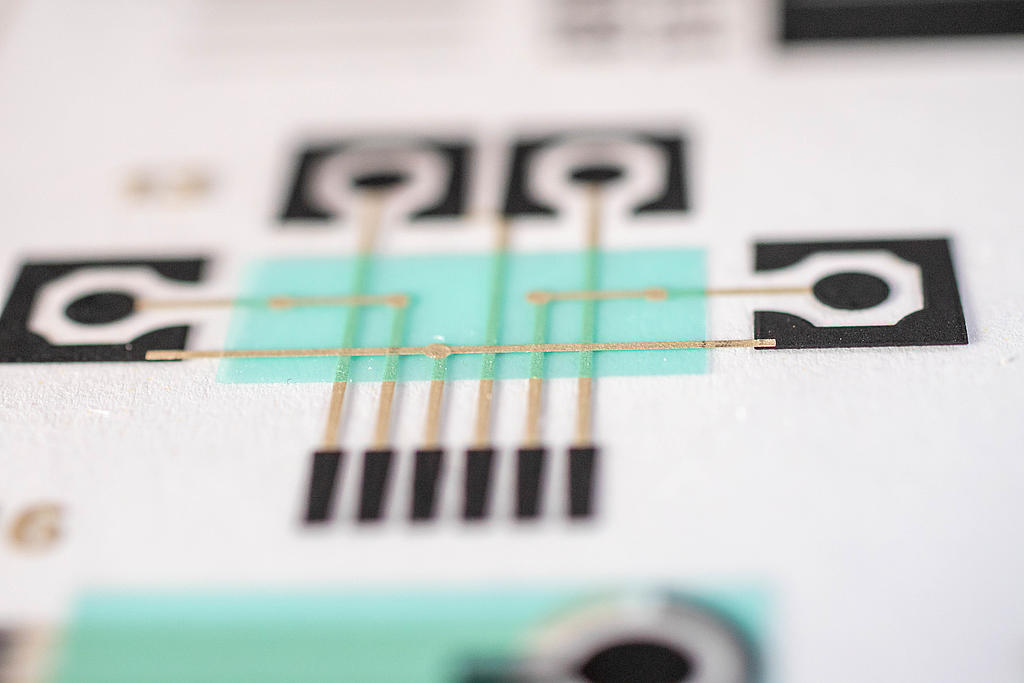

Membrane keyboards are without doubt one of the oldest applications in the field of printed electronics. The application finds use millions of times annually, underscoring the reliability of this technology. The special challenge here is to keep pace with the trend to ever more complex structures in the tiniest space. Printing these in a multi-layer design requires considerable know-how about the materials and processes. The entire range of functional pastes, from silver ink through graphite up to the insulator, is required for this. The ink systems must exhibit good adhesion on several printing substrates and withstand different mechanical loads, such as the bending of a jumper flag and millions of button switching cycles, while always ensuring the electrical function.

Circuit layout

Capacitive IME applications

Thanks to in-mould electronics technology (IME), smart surfaces have attained an entirely new level of importance. Capacitive touch operating elements have long since been realized by printing technology, whereby the conventional elements exhibit only a flat design. IME enables the three-dimensional realization of such input systems in widely different markets.

Consumer products in the white goods industry frequently employ printed electronics for input displays on washing machines and coffee makers. With IME technology, the graphical and functional sreen-printing inks are first printed planograhically , then thermally deformed, and finally back-injection moulded with polycarbonate. This fuses the printed elements together with the polycarbonate to a solid 3D component, which can then be mounted without problems. The savings of space and weight are enormous, while the complexity of the processes and the number of conventional pre-formed parts are reduced substantially. IME is the fastest growing area of printed electronics and already convincing today with its mass implementation.

IMSE Technology from TactoTek

Products

Conductive silver inks

The ELANTAS Europe Printed Electronics sales team offers suitable screen-printing inks and personal advice for your printed electronics applications under AdvancedPrinting@altana.com.

| Description | Drying / Curing | Benefit | |

| Bectron® CP 6662 | Conductive silver ink | 10 min at 120°C | Very flexible, long screen open time, good adhesion to untreated and treated PET films, <0.010 Ω/sq/mil |

| Bectron® CP 6669 | Conductive silver ink | 5 min at 120°C | Fast curing version optimized for a long screen open time, <0.010 Ω/sq/mil |

| Bectron® CP 6671 | UV-curable conductive silver ink | 5 m/min at >700 mJ/cm² UVA and 2 min at 100°C | UV-curable and ultra-low VOC, superior screen open time, <0.030 Ω/sq/mil |

| Bectron® CP 6680 | Thermoformable conductive silver ink | 10 min at 120°C | Optimized for in-mold electronics, <0.025 Ω/sq/mil |

| Bectron® CP 6690 | High temperature conductive silver ink | 10 min at 160°C | Optimized for high temperature applications up to 200°C, good adhesion to ELAN-Film HT 180 and Kapton, <0.015 Ω/sq/mil |

Conductive carbon inks

| Description | Drying / Curing | Benefit | |

| Bectron® GP 9552 | Conductive carbon ink | 10 min at 120°C | Silver top-coat with good adhesion to treated PET films, <40 Ω/sq/mil |

| Bectron® GP 9553 | Conductive carbon ink | 10 min at 120°C | Good adhesion to silver and untreated PET films, <40 Ω/sq/mil |

| Bectron® GP 9580 | Thermoformable conductive carbon ink | 10 min at 120°C | Optimized for in-mold electronics, good adhesion to silver and PC films, <55 Ω/sq/mil |

Insulating inks

| Description | Drying / Curing | Benefit | |

| Bectron® DP 8442 | Insulating ink green | 5 m/min at >600 mJ/cm² UVA | Good adhesion to silver, untreated and treated PET films |

| Bectron® DP 8443 | Insulating ink blue | 5 m/min at >600 mJ/cm² UVA | Good adhesion to silver, untreated and treated PET films |

| Bectron® DP 8444 | Insulating ink colorless | 5 m/min at >600 mJ/cm² UVA | Good adhesion to silver, untreated and treated PET films |

| Bectron® DP 8480 | Thermoformable insulating ink | 10 min at 120°C | Optimized for in-mold electronics, good adhesion to silver and PC films |

For further information about the products described, see the link below. There and in our technical datasheets you’ll find relevant recommendations for additional insulating and conductive screen-printing pastes: https://www.elantas.de/europe/products/printed-electronics/products.html

We’ll be pleased to answer your questions directly and accompany you in the technical implementation of your projects with suitable products from our portfolio. Simply send us an e-mail to: AdvancedPrinting@altana.com